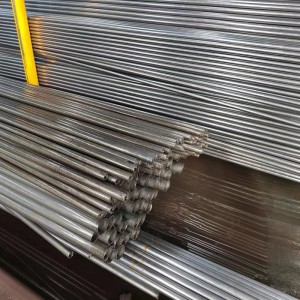

20CrMnTi Alloy Seamless Steel Pipe Tube

Short Description:

20CrMnTi alloy steel pipe is usually low carbon steel pipe with a carbon content of 0.17% -0.24%, also known as gear steel, and many parts are made of 20CrMnTi.

Here are three types of 20CrMnTi alloy steel tubes: cold drawn, hot rolled, and cold rolled bright seamless steel tubes, and the process is different for different needs. However, some units use round steel to produce parts without considering the use of steel pipes instead. Replacing 20CrMbTi round steel with 20CrMnTi steel pipe saves both raw materials and man-hours, which reduces costs and increases market competitiveness. 20CrMnTi and 30CrMnSiA seamless pipes are all carburized steel with good performance, high hardenability, after carburizing and quenching, they have a hard and wear-resistant surface and a tough core, with high low-temperature impact toughness, moderate weldability , Machinability is good after normalizing.

Our mission is always to develop into an innovative supplier of high-tech digital and communication devices by offering price added design, world-class manufacturing, and repair capabilities for 20CrMnTi Alloy Seamless Steel Pipe Tube, We generally offer most effective top quality merchandise and great assistance for the majority of enterprise users and traders . Warmly welcome to affix us, let’s innovate together, and fly dreams.

Our mission is always to develop into an innovative supplier of high-tech digital and communication devices by offering price added design, world-class manufacturing, and repair capabilities for 20CrMnTi Alloy Seamless Steel Tube, Our factory insists on the principle of “Quality First, Sustainable Development”, and takes “Honest Business, Mutual Benefits” as our developable goal. All members sincerely thanks for all old and new customers’ support. We will keep working hard and offering you the highest-quality goods and service.Thanks.

|

Grade |

C(%) |

Si(%) |

Mn(%) |

Cr(%) |

Ti(%) |

|

20CrMnTi |

0.17-0.23 |

0.17-0.37 |

0.80-1.10 |

1.00-1.30 |

0.04-0.10 |

|

Grade |

Rp0.2 (MPa) |

Rm (MPa) |

Impact |

Elongation |

A Z (%) |

Delivery |

Hardness HB |

|

|

|

|

KV (J) |

A (%) |

|

|

|

|

20CrMnTi |

318 (≥) |

967 (≥) |

11 |

34 |

41 |

Solution & Aging, Ann, Ausaging, Q+T |

332 |

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing or Cold Rolling, On line inspection

5. Heat Treatment

6. Straightening/Cutting to specified length/Finished Measuring Inspection

7. Quality Testing in own lab with Tensile Strength, Yield Strength, Elongation, Hardness, Straightness, etc.

8. Packing and Stocking.

100% Eddy Current Testing.

100% Size Tolerance Checking.

100% Tube surface checking to avoid surface defects

Hot Rolled, Annealed, Normalized, Quenched and Tempered

Packaging

1. Bundle packing

2. Beveled end or plain end or varnished as per buyer’s required

3. Marking: as per customer’s requests

4. Painting varnish coating on the pipe

5. Plastic caps at ends

Delivery time

With 15-30 days after full payment received

20CrMnTi Alloy Seamless Steel Pipe Tube

We generally offer most effective top quality merchandise and great assistance for the majority of enterprise users and traders .

20CrMnTi Alloy Seamless Steel Tube

Our factory insists on the principle of “Quality First, Sustainable Development”, and takes “Honest Business, Mutual Benefits” as our developable goal. All members sincerely thanks for all old and new customers’ support. We will keep working hard and offering you the highest-quality goods and service.