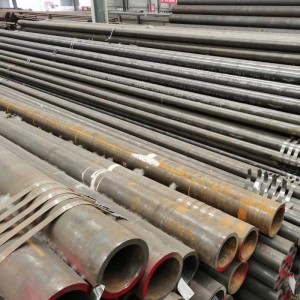

Mechanical tubes are used in mechanical and light structural applications.

Mechanical tubing is produced to meet specific end-use requirements, specifications, tolerances and chemical properties.

Piping for mechanical and light structural applications. This allows for a more specific uniformity of properties throughout the pipe compared to standard pipes or ducts. Mechanical tubes can be produced to standard specifications when required, but are usually produced to "typical" performance, with a primary focus on yield strength for precise dimensions and wall thickness. In some heavily formed applications, the yield strength may not even be specified, and the production of mechanical tubes is "fit for use". Mechanical piping includes a wide range of structural and non-structural applications.

We apply our metallurgical and production expertise to manufacture high-performance seamless mechanical tube products to meet your needs.

This includes carbon, alloys and even custom steel grades; annealed, normalized and tempered; stress relieved and stress free; and quenched and tempered.

Seamless steel pipes for machinery and automobiles, used in the manufacture and processing of automobile trunk and rear axle pipes, precision equipment, instruments and instruments.