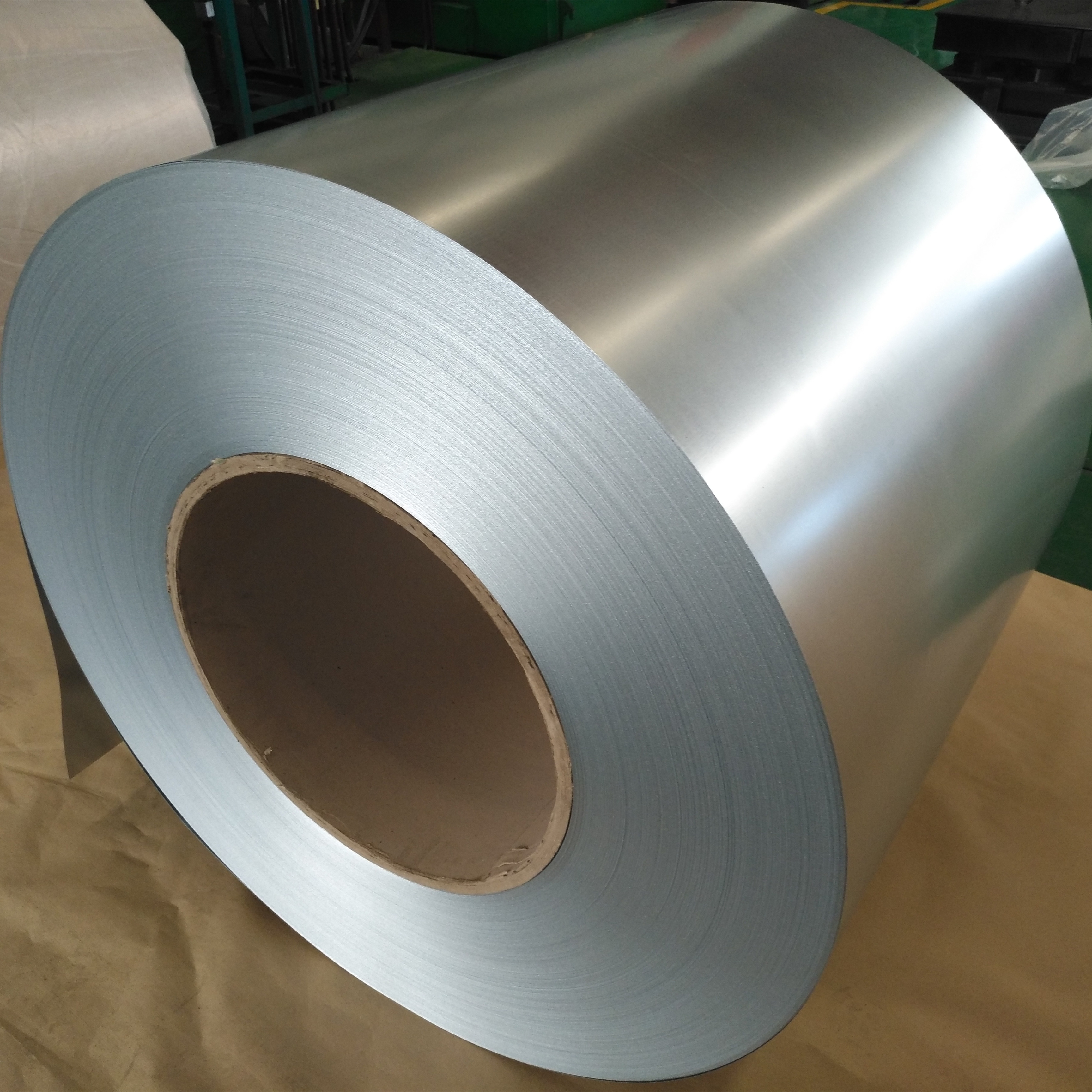

Galvanized Steel Coil

Short Description:

Galvanized coil, A thin steel plate is immersed in a plating tank containing molten zinc so that a layer of zinc adheres to its surface. It is mainly produced by the continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank containing molten zinc to make galvanized steel plate. Galvanized coils can be divided into hot-rolled galvanized coils and cold-rolled hot-rolled galvanized coils, which are mainly used in construction, household appliances, automobiles, containers, transportation and household industries. In particular, steel structure construction, automobile manufacturing, steel warehouse manufacturing and other industries. The demand of construction industry and light industry is the main market of galvanized coil, which accounts for about 30% of the demand of galvanized sheet.

-300x300.jpg)