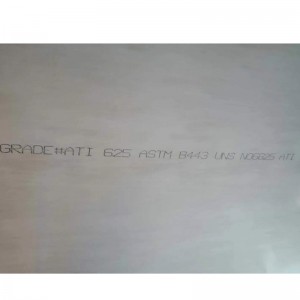

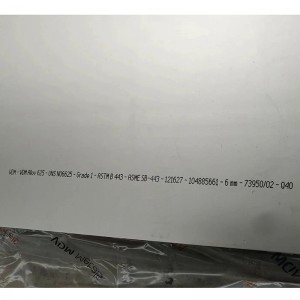

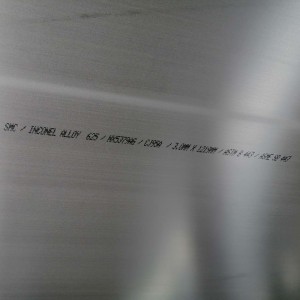

Inconel625/N06625 Alloy Steel Plate

Short Description:

Inconel625 alloy (UNS 6625) is an austenitic superheat resistant alloy mainly composed of nickel, which has excellent properties of extensive oxidation resistance and corrosion resistance.

ERNiCrMo-3 ENiCrMo-3

Supply Product

Plate, Strip, Bar, Wire, Forging, Smooth Rod, Welding Material, Flange, etc. We also can be processed according to the drawing

Components of organic chemical processes containing chlorides, especially when using acidic chloride catalysts; Cooking and bleaching tanks used in the pulp and paper industry; The absorption tower, reheater, flue gas inlet baffle, fan (wet), agitator, guide plate, and flue in the flue gas desulfurization system; Used for manufacturing equipment and components for use in acidic gas environments; Acetic acid and acetic anhydride reaction generator; Sulfuric acid condenser; Pharmaceutical equipment; Industries and products such as bellows expansion joints.

INCONEL 625 is an austenitic superheat resistant alloy primarily composed of nickel. Originating from the strengthening effect of molybdenum and niobium solid solutions contained in nickel chromium alloys, it has ultra-high strength and extraordinary fatigue resistance at low temperatures up to 1093 ℃, and is widely used in the aviation industry. Although this alloy is designed for strength in high-temperature environments, its high content of chromium and molybdenum has high resistance to corrosion media, from highly oxidizing environments to general corrosive environments, with high resistance to corrosion spots and cracking corrosion, demonstrating excellent corrosion resistance characteristics. INCONEL 625 also has strong corrosion resistance against chloride contaminated media such as seawater, geothermal water, neutral salts, and saltwater.

.jpg)

-300x300.jpg)