Li-tubes tse nang le li-welded welded (ERW) tsa motlakase li etsoa ka ho bata ho etsa mohala o bataletseng oa tšepe ka har'a tube e chitja ebe o e fetisa letotong la ho etsa meqolo ho fumana cheseletso ea longitudinal.Joale mahlakore a mabeli a futhumatsoa ka nako e le 'ngoe ka motlakase o phahameng oa maqhubu 'me a petetsoa hammoho ho etsa tlamo.Ha ho tšepe ea ho tlatsa e hlokahalang bakeng sa li-welds tsa longitudinal ERW.

Ha ho na litšepe tsa fusion tse sebelisoang nakong ea tlhahiso.Sena se bolela hore phala e matla haholo ebile e tšoarella.

The weld seam e ke ke ea bonoa kapa ho utluoa.Ena ke phapang e kholo ha u sheba ts'ebetso ea welding ea arc e kentsoeng habeli, e hlahisang sefaha se hlakileng se ka hlokang ho tlosoa.

Ka tsoelo-pele ea maqhubu a motlakase a phahameng haholo bakeng sa welding, mokhoa ona o bonolo haholo ebile o bolokehile.

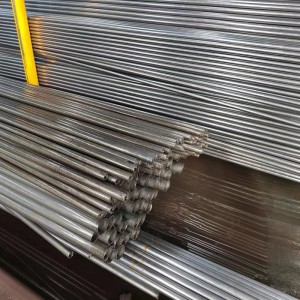

Liphaephe tsa tšepe tsa ERW li entsoe ka "restance" e tlaase-frequency kapa high-frequency resistance.Ke liphaephe tse chitja tse cheselitsoeng ka lipoleiti tsa tšepe tse nang le li-welds tsa longitudinal.E sebelisetsoa ho tsamaisa oli, khase ea tlhaho le lintho tse ling tse nang le mouoane, 'me e ka finyella litlhoko tse sa tšoaneng tsa khatello e phahameng le e tlaase.Hajoale, e nka boemo ba bohlokoa lefapheng la lipeipi tsa lipalangoang lefatšeng.

Nakong ea ho tjheseletsa pipe ea ERW, mocheso o hlahisoa ha hona joale o phalla ka holim'a sebaka sa ho kopana sa sebaka sa welding.E futhumatsa likarolo tse peli tsa tšepe ho fihlela ntlha e le 'ngoe e ka etsang tlamo.Ka nako e ts'oanang, tlas'a ketso ea khatello e kopantsoeng, mathōko a tube e se nang letho e qhibiliha ebe e petetsa hammoho.

Hangata boholo ba pipe ea ERW OD ke 24" (609mm), bakeng sa lipeipi tse kholoanyane li tla etsoa ka SAW.