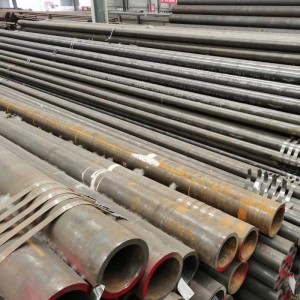

Lipeipi tsa sejoale-joale ke tšepe e nang le k'habone e tlase kapa e tlase-tlase ea khabone, e leng sehlahisoa se nang le litaba tse phahameng tsa tekheniki le boleng bo phahameng bo ekelitsoeng.Boholo ba likatleho tse ncha tsa thekenoloji lefapheng la metallurgical lilemong tse 20 tse fetileng li sebelisitsoe tlhahisong ea tšepe ea liphaephe.Mokhoa oa nts'etsopele ea boenjiniere ba liphaephe ke bophara ba liphaephe tse kholo, lipalangoang tse nang le khase e ngata haholo, pholileng e phahameng, tikoloho e sebelisoang haholo ke kutu, le botenya ba lebota la liphaephe tse ka tlas'a leoatle.Ka hona, tšepe ea sejoale-joale ea liphaephe e lokela ho ba le matla a phahameng, phello e tlase ea Bauschinger, ho tiea ho hoholo le ho hanyetsa brittleness, litaba tse tlase tsa weld carbon le ho cheseha hantle, le ho hanyetsa HIC le H2S corrosion.

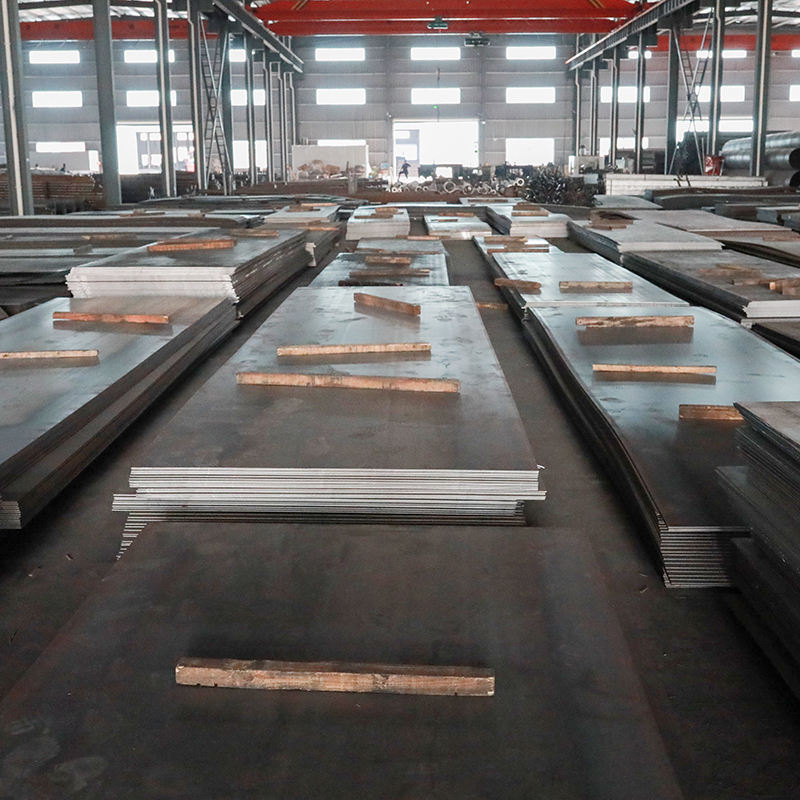

Letlapa la tšepe le sebelisoa ho etsa liphaephe tse cheselitsoeng, hobane liphaephe tse se nang moroallo li entsoe ka litšepe tse chitja, eseng lipoleiti tsa tšepe.Letlapa le letenya le bohareng hangata le sebelisetsoa ho hlahisa phala e teteaneng ea seam e otlolohileng, 'me tšepe ea coil e sebelisoa ho hlahisa phala ea motlakase ea resistane welded(ERW) le phaephe e kentsoeng ka metsing ea arc e kolobisitsoeng (SSAW).Matsatsing ana, bareki ba bangata ba hloka poleiti ea tšepe ea liphaephe ho hlahisa liphaephe tsa mohala hobane lipeipi tsa tšepe li ka sebelisoa ho etsa lipeipi tse kholoanyane tse bophara bo boholo, ho feta moo, theko ea lipeipi tse cheselitsoeng hangata e tlase ho feta ea liphaephe tse se nang moroallo.

Pipe ea tšepe ea tšepe ke lisebelisoa tsa bohlokoa bakeng sa tlhahiso ea phala ea ERW, phala ea mohala oa LSAW, phala ea SSAW, e sebelisoang mohahong oa liphaephe ka lipalangoang tsa oli, khase le metsi, e ka sebelisoa ha ho etsoa kaho ea phetiso ea khatello ea metsi.

Lithempereichara tse tlase haholo tsa arctic, likhatello tse feteletseng botebong ba leoatle, mecha ea litaba ea asiti: esita le maemo a matla ka ho fetesisa ha a na phello e mpe lipoleiting tsa rona tsa linepipe.Lipoleiti tsa linepipe li khona ho sebetsa botebong ba limithara tse 2,800 ka tlas'a metsi a leoatle.

Re boetse re fana ka poleiti ea tšepe e kentsoeng ka har'a lebopo e nang le moalo o thibelang ho bola bakeng sa litlhoko tse phahameng ka ho fetisisa ts'ebetsong ea khase e bolila.Joaloka setsebi sa theknoloji ea sejoale-joale ea thermo mechanical rolling e potlakisang pholiso, re har'a baetapele ba lefats'e ba indasteri.